BUILDING MARYLAND TOGETHER.

‘If you do business in Maryland and you’re not connected with the Maryland AGC, then you are not connected.’

Jeff Kracun, Balfour Beatty & Past Chairman Maryland AGC

This just in:

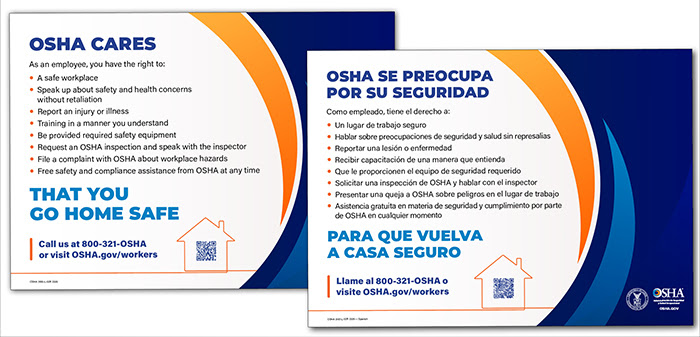

OSHA CARES Poster Available Now!

A message from OSHA:

We want every worker to know that OSHA cares about their wellbeing and is here to help ensure that they go home safe — whether by addressing concerns, providing resources, or offering compliance assistance to employers. The poster that all employers covered by OSHA are required to display in their place of business is meant to remind workers that we are here for them. You can download or order the poster on our website. Note: Employers may choose to use this new version or continue using the prior version they already have on display.

Latest News

- Construction Employment Falls By 11,000 In February With Declines In Residential And Nonresidential As Firms Worry About Demand Levels

Construction employment declined by 11,000 jobs in February, with decreases in both residential and […]

- AGC Releases Member Advisory on Tariffs

This member issue advisory is not legal advice, but rather general policy analysis. As always, […]

- House Subcommittee Weighs Improvements to Brownfields Program

On March 4, the House Subcommittee on Environment held a hearing on legislative proposals relating […]

- FHWA Proposes to Increase Buy America Requirements for EV Chargers

The Federal Highway Administration (FHWA) has issued a notice seeking public comment on a proposed […]

New Member Spotlight

What Our Members are saying

Our Amazing Partners

![Revised_StellaMayC08a-A08cT07a-Z [Converted]](https://marylandagc.org/wp-content/uploads/2024/07/Stella-May-Logo-300x73.jpg)